Design ingenuity: the science and art behind the shield

When we talk about the shield, we often only see its hard appearance and powerful protective ability, but ignore the profound historical and cultural heritage and superb engineering technology hidden behind it. From ancient times to the present, the shield has been one of the important symbols in the evolution of human civilization, witnessing countless battles and changes in peacetime.

The modern shield is not only designed to resist attack, but also an art form that combines mechanics, ergonomics and aesthetics. Engineers carefully consider each parameter-shape determines whether it is convenient to hold; size affects the convenience of carrying; weight distribution is related to the fatigue of long-term use. All these factors together shape an ideal defense tool that is both beautiful and practical.

There are many classic cases in history that show people's pursuit of idealized "armor" in different cultural backgrounds. For example, the standard rectangular Taros style equipped with ancient Roman legions is not only convenient for mass production but also easy to train soldiers to master the use skills. On the eastern battlefield, round or oval wooden frames and leather masked structures are popular, which are light but stable. With the passage of time, contemporary design concepts continue to evolve, and now we see works that integrate the latest scientific and technological achievements: they not only inherit the traditional advantages, but also achieve qualitative leaps in multiple dimensions such as material strength and flexibility.

Material Choice: Building an Unbreakable First Line of Defense

A good defense system is inseparable from high-quality raw material support. For the shield, choosing the right material is the key to ensure its actual combat effectiveness. The most common major materials on the market today include high-strength alloy steels, composite fibers, and new polymers. Each material has its own characteristics:

- High-strength alloy steel: It has extremely high compression resistance and toughness, especially suitable for dealing with heavy blow injuries. However, the relatively high density also means a greater weight burden.

- Composite fiber: is a mixture of carbon fiber and other high-performance fibers. This kind of material is known for its ultra-light portability and excellent wear resistance. It can effectively resist the risk of piercing by sharp objects while reducing the overall load.

- New polymer: This is a new darling that has gradually emerged in recent years. It obtains plastic substrates with special properties through chemical synthesis. It can not only be as strong and durable as metal, but also not easy to deform and damage in high temperature environment.

According to different types of threat situations (such as knife cutting, bullet impact), the above three materials have their own advantages. For example, the police often face the challenge of armed attackers in the performance of their tasks. At this time, composite fiber products containing a large amount of Kevlar components are a good choice. However, the military combat forces need to fight against guns and guns, so they must rely on heavy and dense steel armor to provide all-round protection. Of course, there are many mixed products on the market that combine two or more raw materials in proportion, which can not only integrate the strengths of all parties but also avoid the shortcomings of a single option.

Seiko: Casting the Secret Weapon of Perfect Defense

A qualified shield is by no means a task that can be completed by simple assembly. The entire production process involves many complex processes and technical problems. Let's walk into the production workshop of a large military enterprise! Here, experienced workers are engrossed in the operation of precision instruments, in accordance with strict operating norms for processing. They must not only ensure that each part is tightly sewn together, but also pay attention to issues such as surface finish and flatness, because any slight differences may lead to a decrease in the quality of the final product.

It is worth mentioning that many high-end models also use special coating technology to carry out the last step of beautification and decoration. This approach can not only greatly improve the appearance of grade, but more importantly, it can play the role of anti-corrosion and anti-oxidation and prolong the service life. In addition, some manufacturers have launched personalized customization services, allowing customers to specify colors and patterns according to their preferences or add exclusive logo text and other content, truly different.

Security Partners: Intimate Guardians of Everyday Life

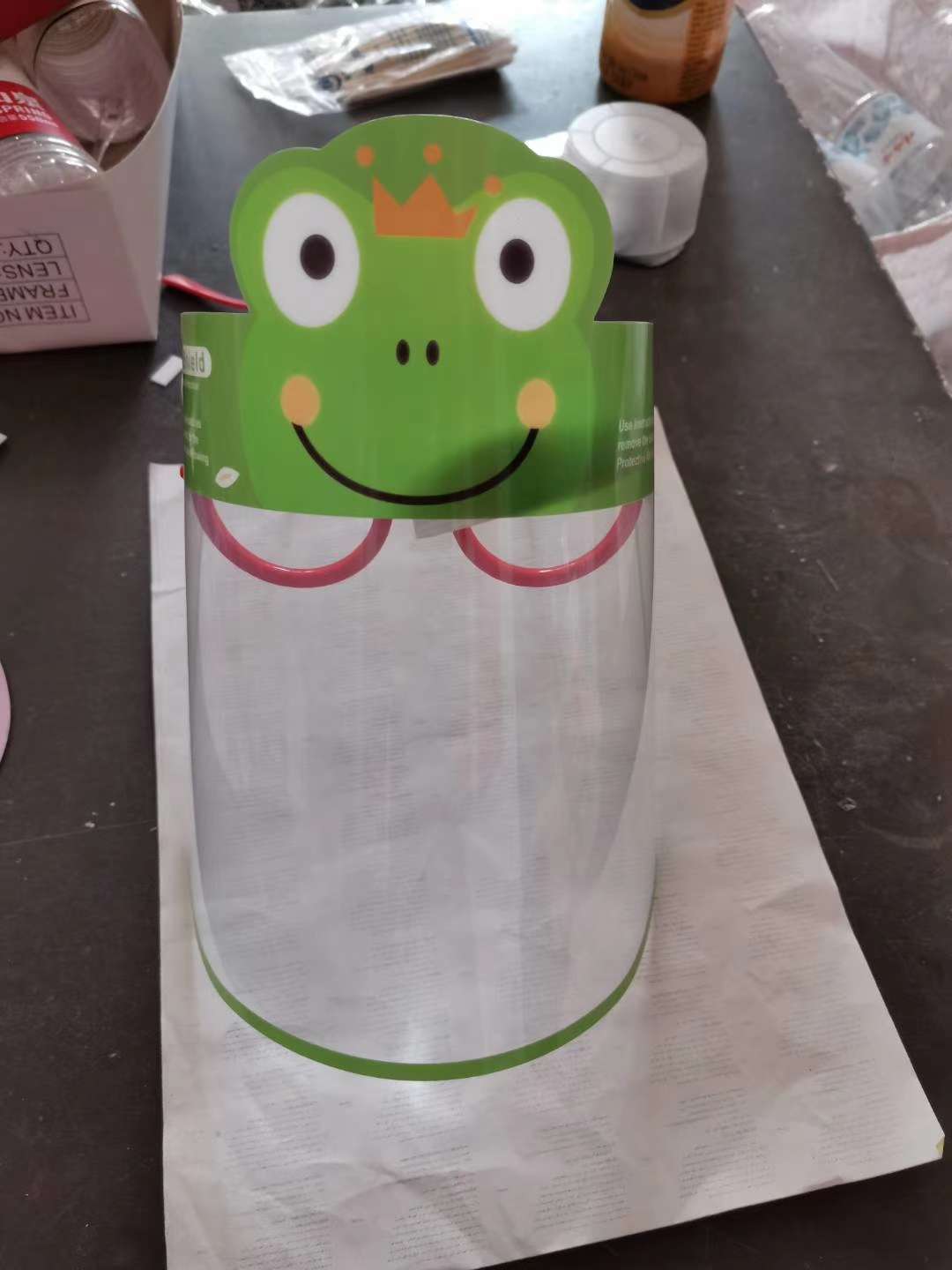

Although most of the time we are not really on the battlefield, there are still many potential sources of risk in daily life waiting to be eliminated. Fortunately, today's civilian-level shields have long gone beyond the scope of military applications and become an indispensable helper around ordinary people. The security guard uncle on duty at the school gate has a small transparent PVC hand-held screen in his hand; the man in charge of night patrol in the community has a rubber soft rubber version of the simple baffle on the waist... These are based on the actual needs of the development of the gadgets, but they do play a role in the critical moment to ensure everyone's safety.

What's more, some private bodyguard teams are equipped with the top professional level equipment in case of emergency. There was once a famous entrepreneur who was suddenly provoked by an unidentified person during a public speech. fortunately, the escort raised the tactical shield prepared in advance to block the opponent's wave