When it comes to shields, many people think of the image of warriors holding heavy armor on the ancient battlefield. However, with the development of science and technology, this ancient tool has already radiated a new vitality. Today's shields are no longer limited to military use, but are widely used in security, law enforcement and industrial protection. By combining advanced materials and precision manufacturing processes, modern shields have become an efficient and reliable protection solution.

Behind each excellent shield, there is a unique design concept and technical support. Most of the high-end shields currently on the market are made of composite materials, such as high-strength polymers and lightweight metal alloys. These materials not only have excellent impact resistance, but also ensure that the overall weight is moderate, easy to carry for a long time. In addition, in terms of production processes, manufacturers usually use advanced molding technology to ensure a smooth surface, and add special coatings to enhance corrosion resistance and wear resistance.

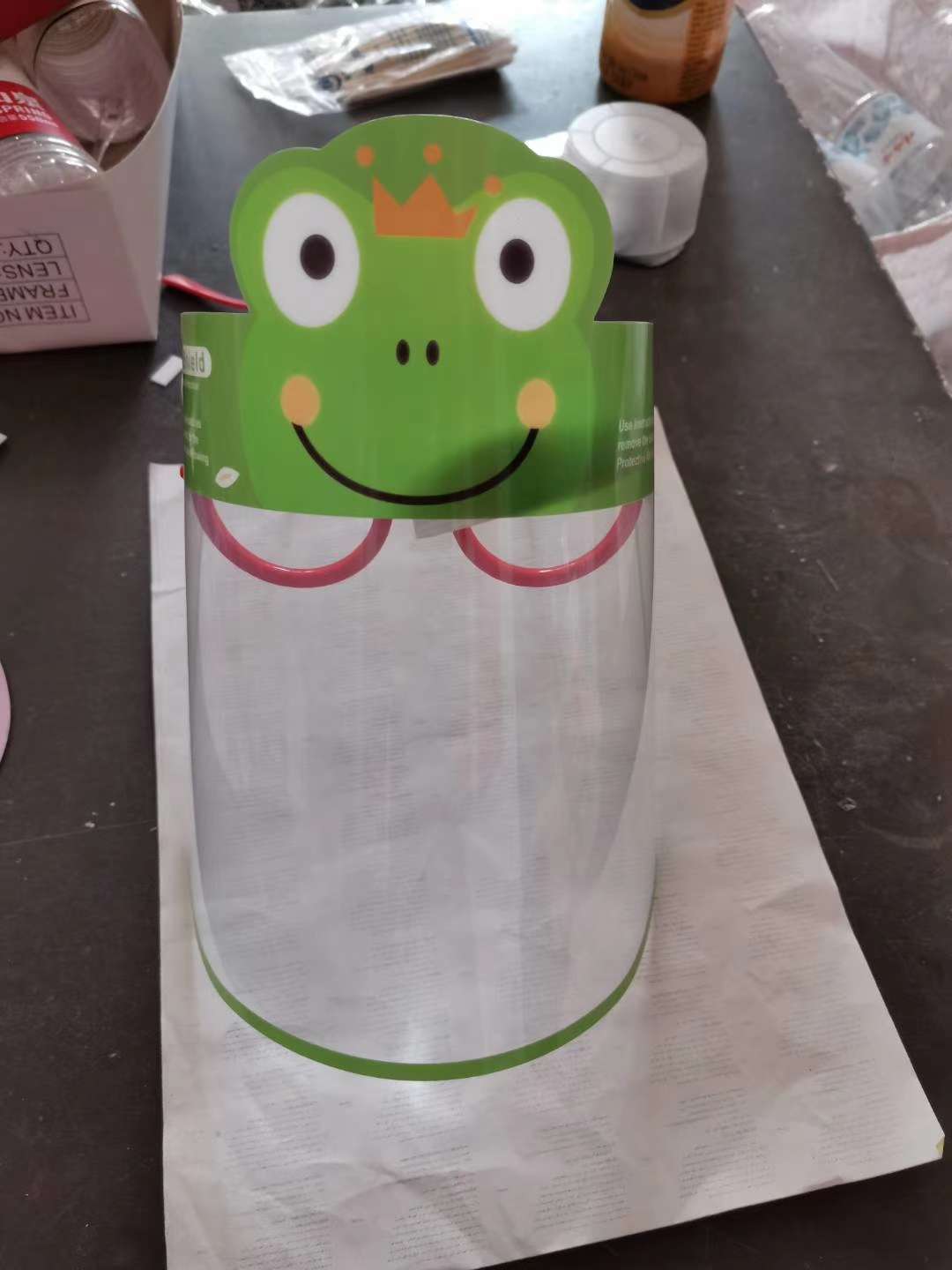

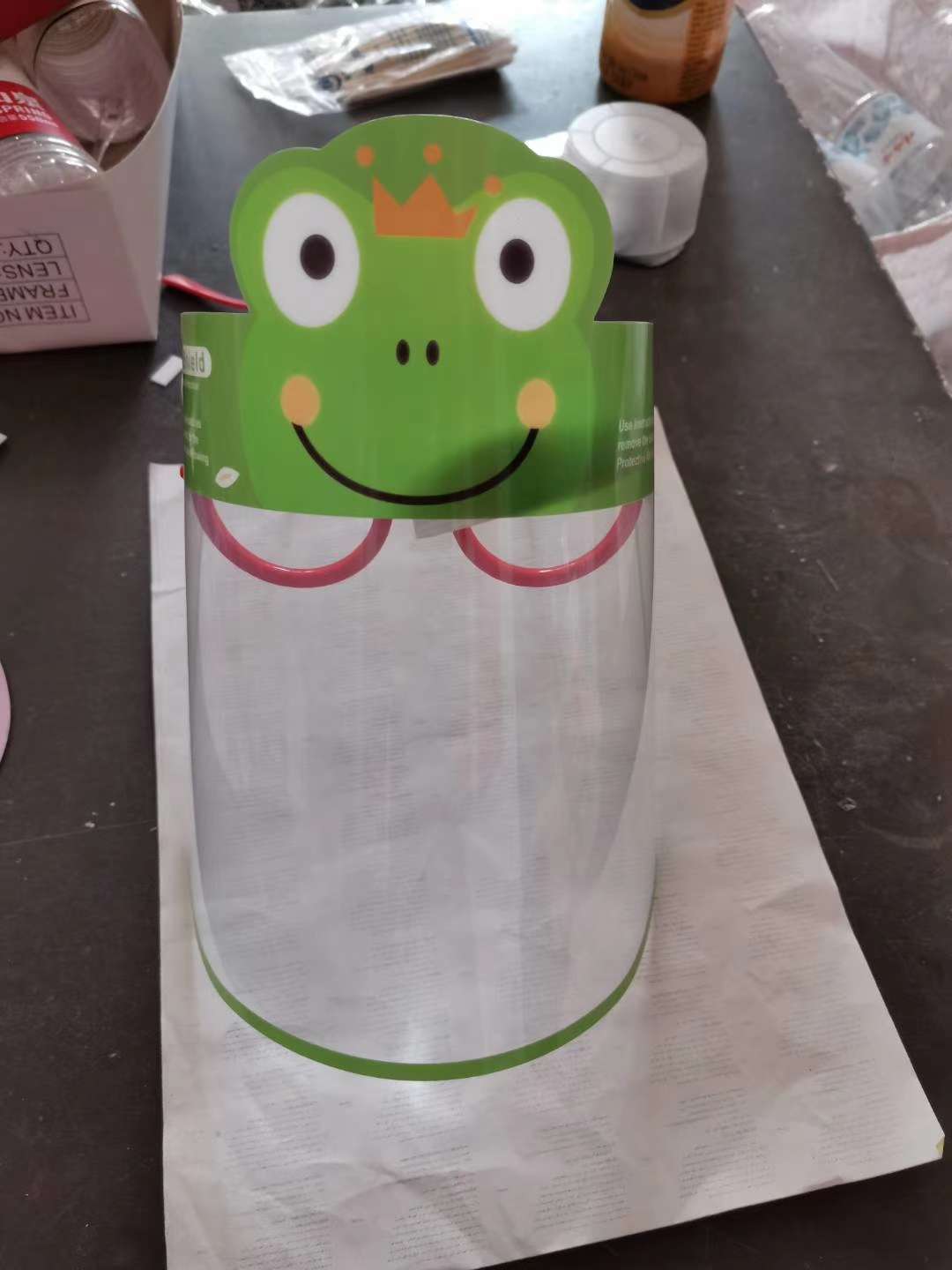

In practical applications, different types of tasks require different types of shields. For example, when the police perform anti-riot tasks, they will choose a large model with a transparent viewing window to better grasp the dynamics of the surrounding environment; while in the factory workshop, they prefer a small portable version for the safety isolation of local areas. Regardless of the situation, a qualified shield should be able to provide users with comprehensive and effective physical protection, so that they can focus on completing their respective work goals.

Of course, the best proof comes from the user's own experience. Many front-line users have said that this new model of shield has brought them an unprecedented sense of security. "I used to worry that insufficient equipment would affect work efficiency," said a driver who has been engaged in dangerous goods transportation for a long time. "But since I changed to this brand, I don't have to worry about these problems anymore." There are many positive feedback like this, which further confirms the excellent quality performance of this series of products.

if you are looking for a shield that suits you, be sure to consider the following key elements: first, specify the specific usage scenario requirements, and then carefully compare the parameters of each product, including but not limited to material type, thickness range, and additional function configuration. Finally, we should also pay attention to check whether the after-sales service terms are perfect and reliable. After all, a detailed and worry-free after-sales commitment is also very important.

Looking ahead, we can foresee that more cutting-edge scientific and technological achievements will be gradually integrated into the research and development of the next generation of shields. AI-driven data analytics systems can help monitor potential threats in real time and automatically adjust defensive posture; nano-scale coatings are expected to significantly increase the surface hardness of existing products while reducing maintenance frequency ...... All of this will make the future protection experience more intelligent, convenient and solid.